Zipline Internship

During the summer of 2023, I worked as a Mechanical Engineering Intern at Zipline in South San Francisco, CA. I contributed to the Structures, Mechanisms, and Hardware Integration (SMI) team that is focused on designing the aircraft for Zipline’s Platform 2 drone delivery system.

Over the course of 12 weeks I owned the design and assembly of an end-of-line tester for the primary structure in the P2 drone.

Context

The primary structure is the main structural body of the P2 drone

Large carbon fiber piece

Includes fuselage, inboard wings, and booms for hover motors as well as numerous mounting points for modules

(Images of primary structure not included in personal portfolio)

The end-of-line tester verifies the structural integrity of each primary structure before it continues onto production assembly

Lives at the manufacturing facility of our international manufacturer

Applies the maximum expected loads

My Contributions

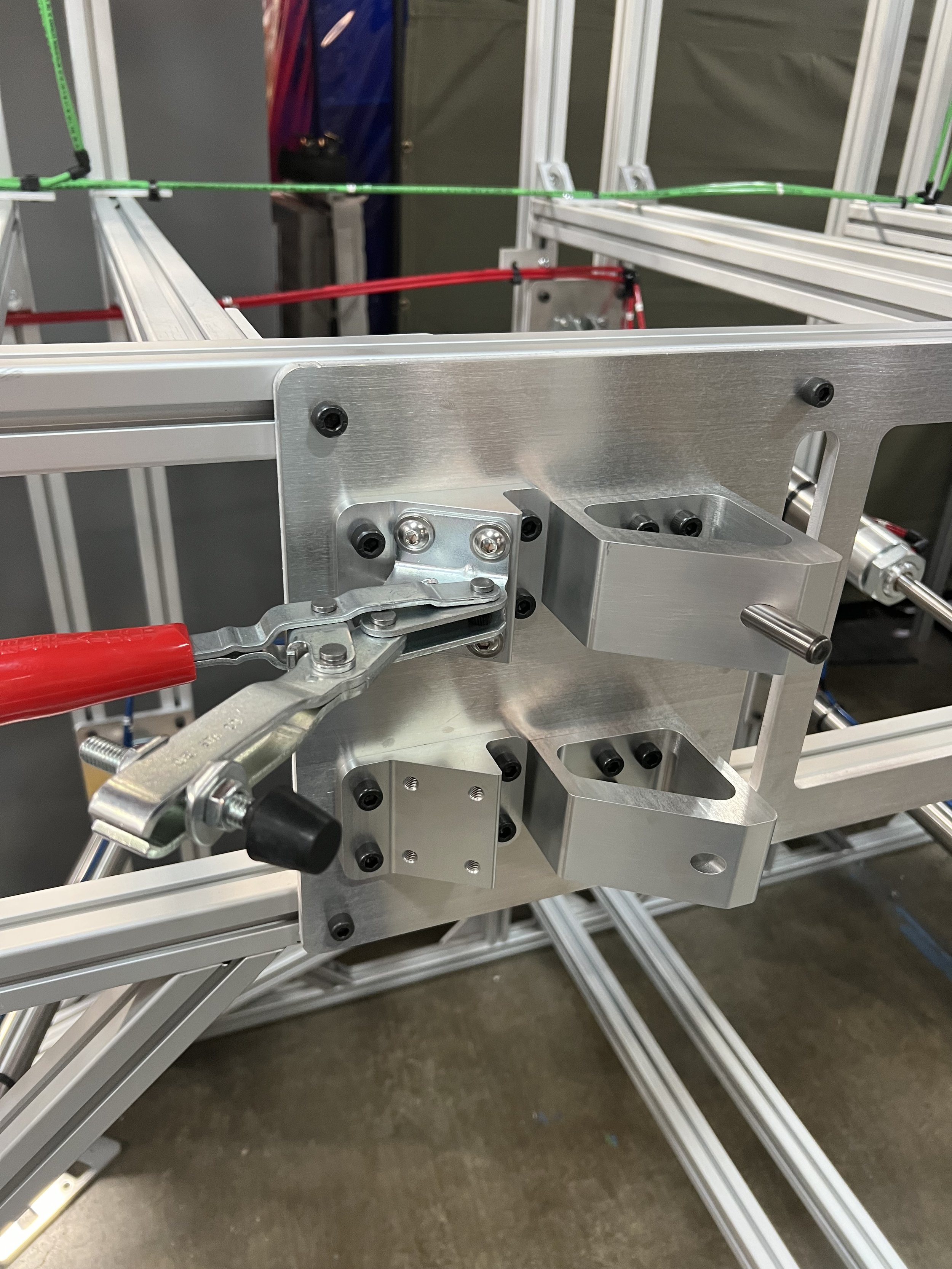

Was responsible for creating overall architecture of tester

Selected orientation and order of operations for fixturing and load application that optimized for:

Technician safety and ergonomics

Accurate representation of stress distribution in test articles from maximum expected loads

Measurement of loads and displacements

Resulted in a tester that can apply 8 unique end-of-line load cases to the primary structure

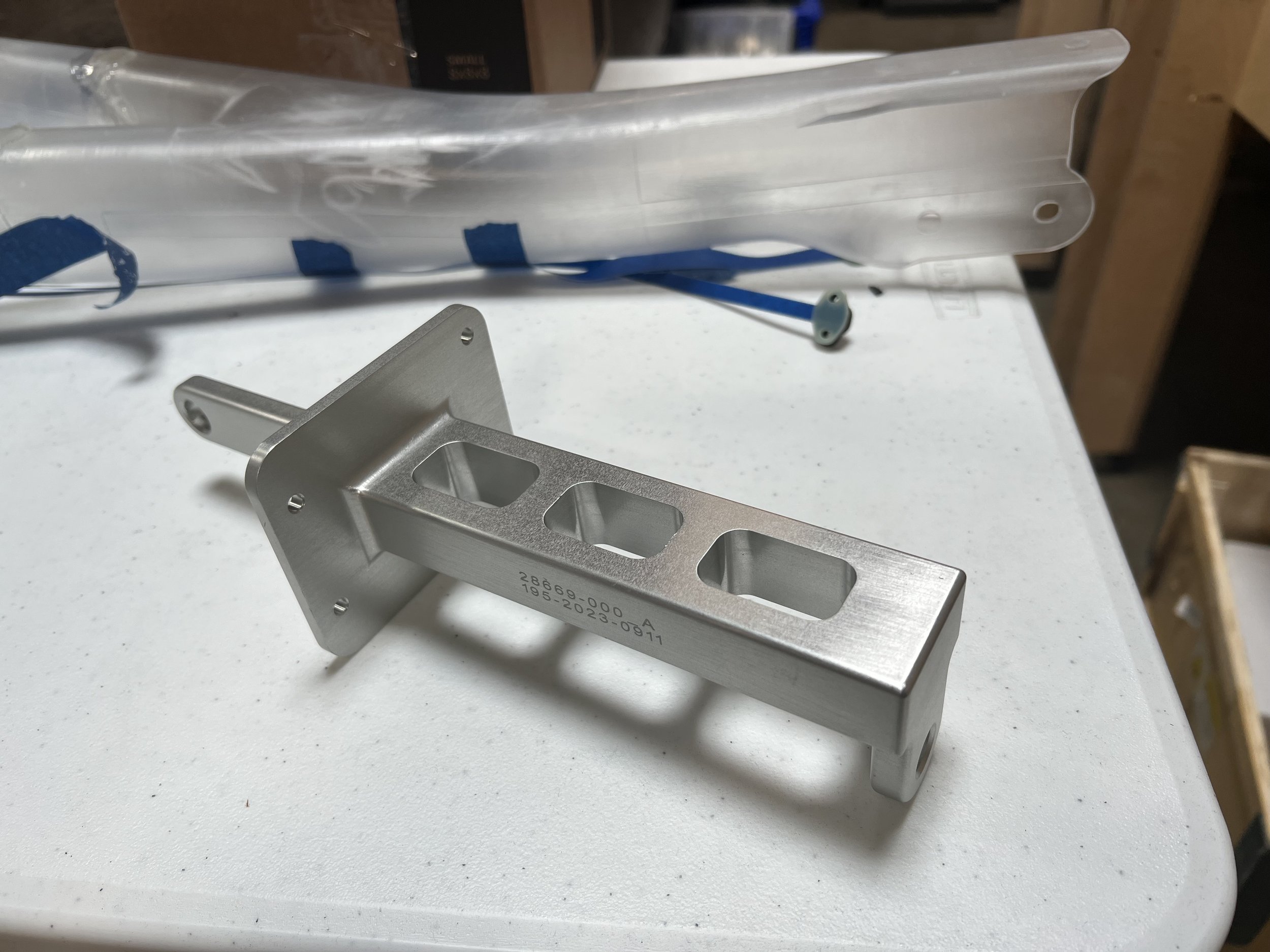

Utilized NX to design 8020 frame assembly and 8 custom machined and laser-cut aluminum parts for interfacing with and fixturing the primary structure

Collaborated with cross-functional teams to realize tester in 12 weeks

Worked in parallel to the development of the end-of-line loads determined by the structural analysis team

Worked with test technicians and programmers to design pneumatic schematic and test program

Assembled entire tester for Zipline’s in-house testing

Managed project schedule and large CAD assemblies

Drafted in-depth design overview and standard operating procedure documentation for second tester to be assembled at manufacturer oversees